Call Us :

+8613539043381

Email Us :

marketing@databeyond.com

The MRF (Material Recovery Facility) is at a critical turning point, transitioning from extensive expansion to high-quality development. On one hand, regulatory oversight in environmental protection, safety, and taxation continues to tighten; on the other, rising labor costs and recruitment difficulties have become the "new normal." Traditional MRFs are trapped in a "triple squeeze": soaring compliance costs, chronic labor shortages, and inefficient operational management.

In this context, building intelligent, automated, and digitalized MRFs is no longer just about "improving efficiency." It has become a strategic cornerstone for enterprises to navigate industry cycles and build long-term competitiveness.

I. Industry Status: Structural Pain Points of the Traditional Model

1) Insufficient Compliance and Stability

Traditional "unorganized and polluting" workshops generally lack environmental facilities, have poor working environments, and maintain incomplete records. Facing normalized inspections, they risk production halts, closures, or relocation, making long-term stable operation difficult.

2) Constraints in Supply Chain and Quality Control

Relying on manual sorting inevitably leads to fluctuations caused by subjective judgment, skill levels, and fatigue. This results in unstable output purity and highly non-standard products, making it difficult to consistently tap into the high-end recycled material market.

3) Opaque Management and Experience-Based Decision Making

Raw material warehousing often relies on visual estimation, making it hard to visualize moisture and impurity levels. Without real-time data support, managers’ decisions often fall into the high-risk trap of "relying on intuition."

II. DATABEYOND Solution: Full-Process Intelligence and Visualization

The DATABEYOND Turnkey MRF Solution reshapes the entire chain from raw material intake to finished product dispatch, building a transparent, efficient, and compliant modern sorting system.

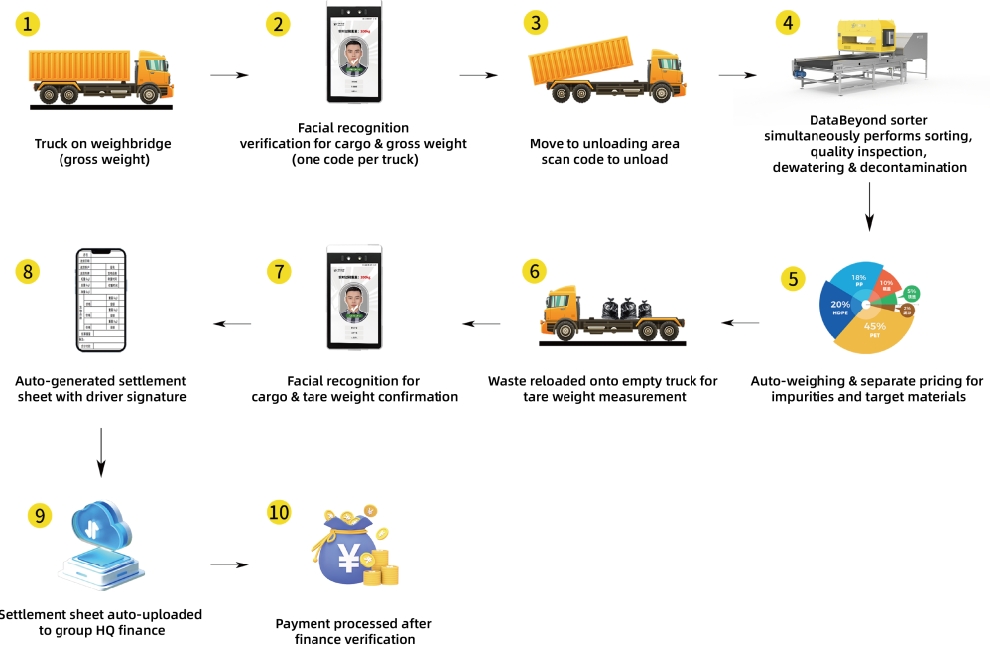

1) Intelligent Receiving System: The "Gatekeeper" of Fair Trade

●Auto-Identification & Weighing: Automatic vehicle info entry reduces manual intervention and closes "favoritism loopholes."

●Composition Analysis & Deduction: Visual indicators replace empirical estimation, ensuring every ton of material is "accounted for and justified."

2) Intelligent Sorting: The 7×24 Intelligent Sorting System"

As the core of the production line, DATABEYOND combines AI Optical Sorters with Embodied Robots to achieve a mix of large-scale front-end sorting and flexible back-end sorting:

●Precise Multi-Category Recognition: Stable sorting of PET, HDPE, PP, meal boxes, Tetra Pak, waste paper, film, glass, etc.

●Standardized Output: Sorting results are unaffected by emotion or fatigue, ensuring consistent production quality.

●High Purity: Sorting accuracy≥ 99.6%, enabling access to high-end downstream markets.

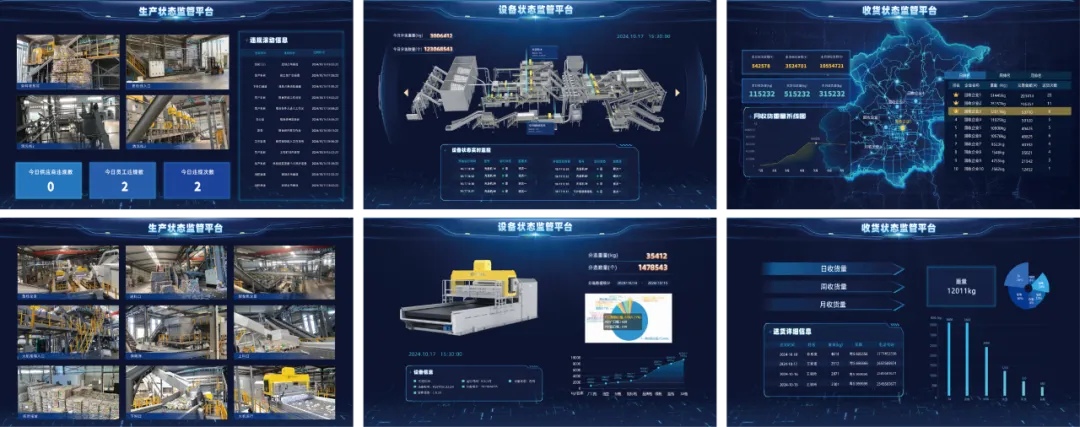

3) AI Agent Factory Management System: The "Factory Brain"

Managers can monitor real-time data via mobile or PC:

●Key Metrics: Equipment status, producations output, and yield rate.

●Inventory Structure: A clear view of intake, output, sales, and process loss.

●Decision Support: Replacing empiricism with data to continuously optimize profit and efficiency.

III. Cost Reduction, Efficiency, and Compliant Development

The DATABEYOND Intelligent MRF Solution delivers three core values:

●Cost Reduction (Labor Savings): Moving toward low-labor or fully automated operations.

●Efficiency Gains (Premium Pricing): Superior purity and higher throughput result in stronger bargaining power.

●Compliance (Sustainable Operation): Traceable data flows and clean environments ensure long-term, sustainable operation.

IV. Reshaping Resource Value, Securing Resource Safety

Recycled resources should not be synonymous with "dirty and disorganized" but should be seen as "Urban Mines" driven by technology. As automation and digitalization deeply integrate into the industry, intelligent MRFs will accelerate the transition toward a higher-value-add future.

V. Intelligent MRF Case Studies (Partial List)

Tianjin Baoyuan MRF

Taiwan Youxiang MRF

Malaysia MRF

Nanjing Feibao MRF

Jinan Ruining MRF

Dongguan Changan MRF

Shenzhen Longgang MRF

Xingtai Supply & Marketing (Juyou) Digital MRF

Putian Shanying MRF

Leave A Message

Scan to Wechat :

Scan to WhatsApp :