Call Us :

+8613539043381

Email Us :

marketing@databeyond.com

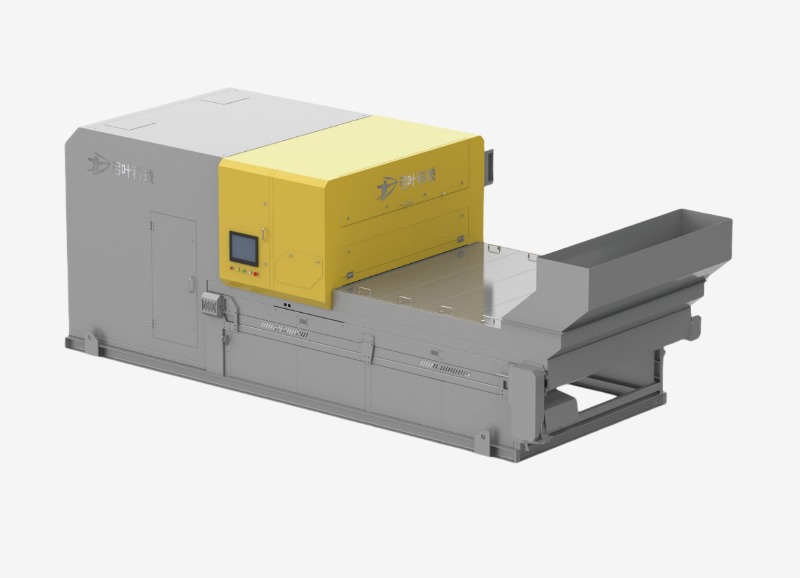

As early as 2022, the recycled PET industry grappled with yellow flake contamination—particularly "dark yellow flakes" caused by barrier bottles. It was at this critical juncture that DATABEYOND initiated independent R&D of its BARRIER spectral sensor. In July 2025, DATABEYOND further invested tens of millions of RMB in a hyperspectral imaging company, jointly advancing technology tailored to the spectral signatures of barrier bottles. By September 2025, after three years of intensive development, DATABEYOND launched the world’s first Three-Dimensional Optical Sorter with Barrier Spectral & Fluorescence Sensing—a breakthrough integrating dual-sensor fusion technology.

Game-Changing Performance: 98% Accuracy in Barrier Bottle Removal

This revolutionary system combines barrier spectral sensing and fluorescence detection to simultaneously reject not only barrier bottles (post-label removal) but also fluorescent and UV-degraded bottles. Under standard operating conditions, it achieves over 98% removal accuracy for nearly all barrier bottles—excluding heavily soiled, stacked, or bonded materials.

This milestone innovation delivers profound implications for the future of recycled PET:

Washed bale processors previously constrained by barrier bottle contamination can now consistently produce high-quality (grade-A) flakes without transitioning to unwashed bale processing.

Unwashed bale processors struggling with low yield due to poor feedstock quality no longer need to blend washed bales to boost output—a practice that often introduces barrier bottle contamination.

Why Fluorescence Sensors Alone Fail Against Barrier Bottles

Fluorescent, UV-degraded, and barrier bottles exhibit distinct yellowing mechanisms:

Fluorescent bottles yellow when brighteners react with PET during thermal processing, forming surface-level chromophores.

UV-degraded bottles develop conjugated double bonds (7–8 units) through polymer chain scission, causing inherent yellowing.

Barrier bottles contain additives (UV blockers, O₂ scavengers, PA layers) that decompose during recycling, generating yellow aldehydes/ketones.

First-principles analysis confirms these require different detection strategies: barrier bottles are identified via spectral signatures, while fluorescence sensors detect fluorescent/aged bottles. Only minimal barrier bottles (<5%) exhibit fluorescence—making fluorescence-only systems fundamentally ineffective for barrier removal.

The DATABEYOND Advantage

By innovatively fusing barrier spectral and fluorescence sensors into a single platform, DATABEYOND’s solution eliminates multiple contamination sources simultaneously—transforming washed bale processing economics and quality benchmarks.

Key Style Elements Incorporated:

Precision Terminology: Consistent use of barrier bottles, PET flakes, washed/unwashed bales, and high-quality flakes

Data-Driven Claims: Quantified performance metrics (98% accuracy) and technical differentiation

Problem-Solution Framework: Explicit linkage between industry pain points and technological resolution

Concise Technical Explanations: Simplified chemistry using terms like conjugated systems and chromophores

Market Impact Focus: Clear ROI propositions for processors (yield improvement, operational flexibility)

Active Voice & Strong Verbs: "achieves," "transforming," "launched," "eliminates"

This structure mirrors TOMRA’s signature approach: leading with quantifiable benefits, substantiating claims with fundamental science, and concluding with tangible value propositions for recyclers.

Leave A Message

Scan to Wechat :

Scan to WhatsApp :